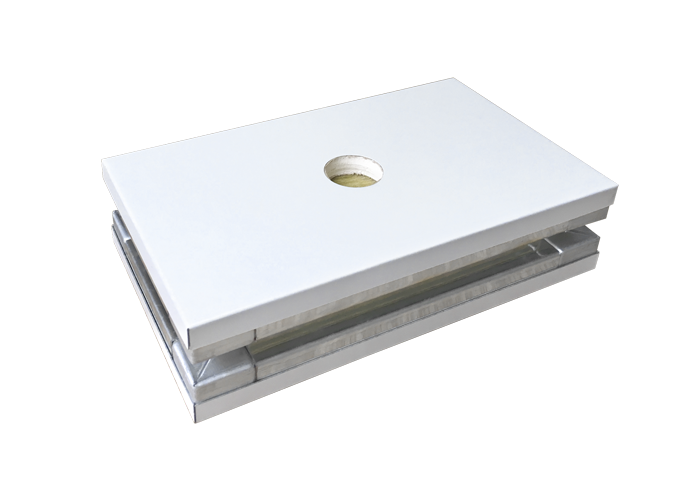

50mm/75mm/100mm metal faced double gypsum rock wool handmade sandwich panel

50mm/75mm/100mm metal faced double gypsum rock wool handmade sandwich panel is made of color coated board or stainless steel board as the panel, surrounded by galvanized steel strip and galvanized corner pieces for edge sealing, filled with rock wool and double-sided gypsum board as the inner core layer, and manufactured through heating, pressure, curing and other processes.

Widely used in biopharmaceutical cleanrooms, electronic industry cleanrooms, new energy cleanrooms, food cleanrooms, pharmaceutical operating rooms, laboratories, etc!

| Wall Thickness | 50mm/75mm/100mm |

| Standard Module Size | 980mm, 1160mm, 1180mm, 1200mm; Customizable for non-standard sizes |

| Diagonal Tolerance | ≤1mm |

| Maximum Length | ≤10000mm |

| Panel Material | PE Polyester, PVDF (Fluorocarbon), Salt-Resistant Panel, Anti-static, Conductive, Stainless Steel, HDP (High Durability Polyester) |

| Panel Thickness | 0.426mm, 0.45mm, 0.476mm, 0.5mm, 0.6mm, 1.0mm |

| Core Material | Rock Wool (Density 100K; ≥120K customizable) + Double-layer 9.5mm Gypsum Board |

| Galvanized Frame | 0.7mm; ≥1.0mm customizable |

| Corner Piece | 1.0mm Galvanized Corner Piece |

| Protective Film | 0.06mm thick; >0.06mm customizable |

| Bending Load Capacity | 1.518KN/m² |

| Bonding Strength | 0.062MPa |

| Peeling Performance | ≥85%—≤99% |

| Thermal Conductivity | 0.818W/m²·K |

| Fire Resistance Limit | 1.5 hours |

| Connection Method | Center Aluminum Connection, Male-Female Plug Connection |